|

||||||||

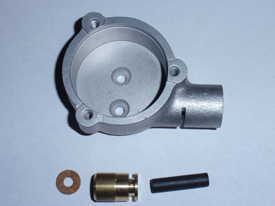

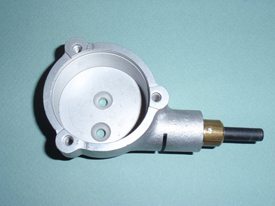

1958–1965 Nozzle Block Brass Cup Bottom Replacements In the past, a nozzle block with a damaged cup bottom was not useable. We developed a process several years ago to replace the damaged cup bottom and it works successfully. Two replacement brass bottoms are soldered in place. This repair is stronger than the original cup bottom and is undetectable when your FI unit is installed. The cost for two replacement brass bottoms is $50.00 which is less than the cost of a new reproduction nozzle block.

I offer a service to correct the problem of gasoline leaking around the fuel valve. This happens when the fuel valve fit is relatively loose. This excess gas entering the fuel meter could even overflow out the top of the fuel bowl while the engine is running. The steel fuel valve (starting piston) rides in an aluminum bore that must fit very closely around it to prevent such dangerous leaks. The potential for this situation to occur doesn’t seem to be widely known or discussed. However, if there is a tight fit of the fuel valve (starting piston) in its bore, gasoline cannot flow around it and into the spill valve after the engine starts. If you have a fuel valve fit that is too loose (more than .001” side clearance), my service can custom machine a new oversize fuel valve and bore your fuel bowl to match it. This will allow the starting by-pass circuit to seal off gas flow as it was designed to do while the engine is running. The cost of this service is normally in the $150 to $250 range. The exact cost depends on the condition of your fuel bowl and whether or not bore sleeving is required.

Some fuel injection repairs require aluminum welding, alignment fixtures, and precision tooling that aren’t available in most automotive shops. My business specializes in these types of repairs. We have the experience, new parts, and special equipment necessary to complete them in-house. For example, few people today have the knowledge, tools and experience to replace the brass bushings for the butterfly shaft in the air meter. Another service provided is repairing the check ball mechanism in the 4360 cold enrichment (choke) housing.

These are some other specialty repairs I can provide:

|